Masonry Paint Flaking Over Oil Bound Distemper/Limewash

Masonry Paint Over Oil Bound Distemper Flaking

Distemper See Limewash

Distemper See Limewash

A water based breathable coating based on chalk to which coloured pigment be added.

Limewash/ Soft Distemper Flaking

Limewash/ Soft Distemper Flaking

Cause

The characteristics of both products are similar and binders can be added to both for external use.

When underbound surfaces are present often an alkali resisting primers or stabilising solutions are recommended to consolidate the powdery surface. While this will bind the top layer to overcoat with Acrylic, PVA water based finishing paints over a period of time problems as shown can occur.

In the illustration the failure is because the tensile strength of the top coats is greater than its adhesion onto the underbound material causing cracking, shrinkage and subsequent flaking.

Remedy

Remove all loose, flaking material by the most appropriate means followed by washing down to remove all underbound material and allow to dry.

Priming.

Apply one coat of stabilising solution by brush to consolidate the residual powdery material.

Note, after the application of the stabilising solution should the surface appear glossy then this should be thoroughly abraded before applying water based PVA and Acrylic based paints.

Finishing coats.

Apply the selected finishing paint, following the manufacture's instructions, including any necessary Personal Protective Equipment.

For further product information:

https://www.duluxtradepaintexpert.co.uk/en/services/architects-specifiers

https://www.johnstonespaint.com

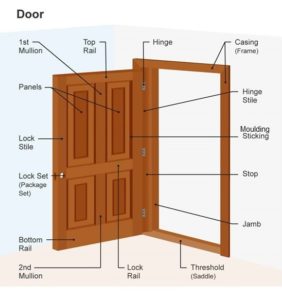

Door Components

The component of a door as shown in standard although in certain parts can vary in description.

The alternative names can relate to:

Casing - Refers to the Architrave moulded or plan trim around the door frame.

Door frame - can also be known as Door liner which is fitted into the Door opening.

A door from can be of solid wood which is rebated to incorporate the door stop.

A Door lining is normally thinner and the door stops are supplied a separate item.

Sticking - refers to the moulding surrounds of the panels.

Door Threshold also known as the Door Saddle incorporated on external doors

Door Furniture. Comprises of the hardware : including Lock, Handles, Escutcheons (key hole cover), Finger plate, Kicking plate.

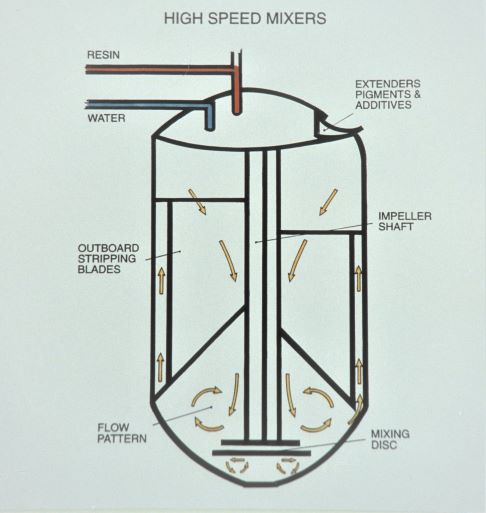

How is water based paint made

How is water based paint made?

How is water based paint made?

The components for a decorative water based paints are different to those for an oil based product and consist of a resin/binder which generally is either Polyvinyl Acetate (PVA) or Acrylic resin containing a coalescent solvent which helps to bind , Pigments (the same as used in oil paints), Thinner (water) plus various additives such as anti-foaming, to stop aeration of the product particularly when applied by roller and leaving pin holes in the surface), thickening agents to give body and biocide(to stop mould growth within the container).

Unlike oil based paints the manufacture of water based paints is easier byway of dispersing pigments and extenders into a solution of water and resin PVE (Polyvinyl Acetate) using high speed mixers.

The range of water based coatings is extensive and manufacturers different formulations depending on their market target.

In general the variants in raw material can lead to product description being similar but product quality can be different with the lower cost material not always offering the same coverage power (opacity) flow (reducing brush or roller marks) and washability.

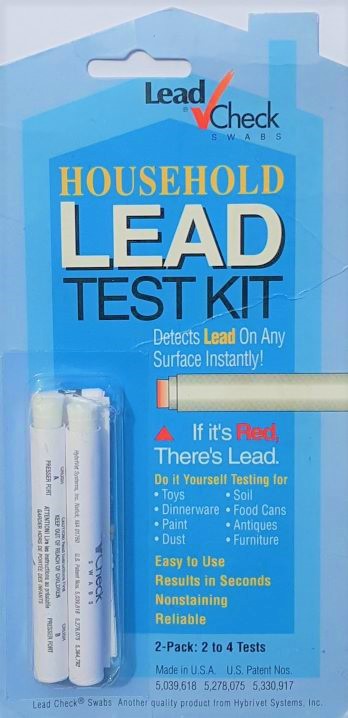

Lead Based Paints

There was an increased awareness of the environmental issues relating to paint during the late 1960’s when Lead used as a pigment was prohibited from all building paints.

There was an increased awareness of the environmental issues relating to paint during the late 1960’s when Lead used as a pigment was prohibited from all building paints.

See Health and Safety: Lead based paints.

This directive was instigated by the Greater London Council (GLC) for all paints used on interior trim work. Soon this directive was followed by other major metropolitan authorities.

The exclusion of lead as a pigment and the changes made resulted in decorative building paints becoming easier to apply for both the trade and retail markets.

Lead may be present in properties built before the 1980's especially where the overall paint thickness of the existing coatings is high.

If Lead is suspected then portable Lead Testing Kits will assist. Alternatively, consultancy companies are available to carry out site surveys.

It is essential that any suspected lead based paint removed is bagged up, sealed and labelled 'contaminated material'.

Disposal should be in accordance with local authority instructions.

For further information: https://www.hse.gov.uk/pubns/cis79.pdf

Quality Control and Laboratory Testing

Typical Works Laboratory.

Quality control is the most important of all the areas associates with paint manufacture.

The illustrations show some of the quality assurance tests carried out to ensure the batch to batch production meets the requirements for colour, consistency, durability, application and appearance.

Blue wood staining

Blue wood staining.

As the wood has been stained by moisture, the staining may be difficult to remove, therefore the application of clear or translucent coatings may not be successful, therefore, repainting with opaque finishes maybe required.

For repainting with opaque coatings the following system is suggested.

Preparation.

Check that the moisture content within the wood is below 20%, if not then forced drying may be necessary.

Thoroughly sand down and remove all surface contaminants to leave the surface clean and dry.

Apply one coat of Fungicidal Solution and allow to dry. Re-check the moisture content before painting.

An application of Oxalic Acid (wood bleach) my help to remove part of the staining

Priming /Undercoat /Finishing.

Apply a microporous coating oil or water based, opaque or translucent in accordance with the selected manufactures recommendations.

Microporous paints can be obtained from manufactures such as:

Jotun Paints (Europe) Ltd. Demidekk : https://www.jotun.com/Datasheets/Download?url=%2FTDS%2FTDS__28142__DEMIDEKK+Ultimate+Opaque+Coating__Euk__GB.pdf

Johnston's Paints. https://www.johnstonestrade.com/product/flexible-gloss

Dulux Trade Paints. https://www.duluxtradepaintexpert.co.uk/en/products/products-listing/all

Powder Coated Surfaces Repainting

Powder coated metal

When due to damage, fading or other reasons repainting is require then a specific specification is required.

To apply a conventional oil based paint system is not advisable as adhesion problems can be encountered.

Recommended Specification.

Remove by the most appropriate means, all surface contaminates, dust, dirt, loose or otherwise defected material back to a firm edge .

Feather off all edges with suitable grade abrasive paper to a smooth surface leaving it clean and dry.

Painting.

Priming.

As special adhesion and metal primers are recommended, contact should be made with the selected manufacture to enquire of their specific recommendations and systems.

Note: The following manufactures product range include suitable materials.

Bradite. http://bradite.com

Dulux. https://www.dulux.co.uk/products-listing

Zinsser. http://www.zinsseruk.com/product

Johnstone's https://www.johnstonestrade.com/products

Powder Coated Metal

Powder Coated Metal

Cause

Failure of powder coated hand rails due to mechanical damage or poor preparation of the metalwork prior to coating.[/caption

Causes

Powder coatings have benefits over a conventional oil based building paints, but when problems arise, then special treatment is required. (See specifications).

Other problems can arise besides those illustrated and can be caused during the application process. Bittiness can result in the work not being properly cleaned prior to spraying. Bittiness can also result in weld spatter not being removed and may have to be ground off to provide a smooth surface.

Uneven application is generally associated with incorrect air pressure setup. During application the applicator should maintain continuous gun movement and a high film-thickness in areas, can result in an orange peek effect. If the item sprayed is uncured, then this is suspected then upon impact chipping can occur.

Under curing can also lead to surface bloom.

Remedy

See Powder coating repainting in specifications.

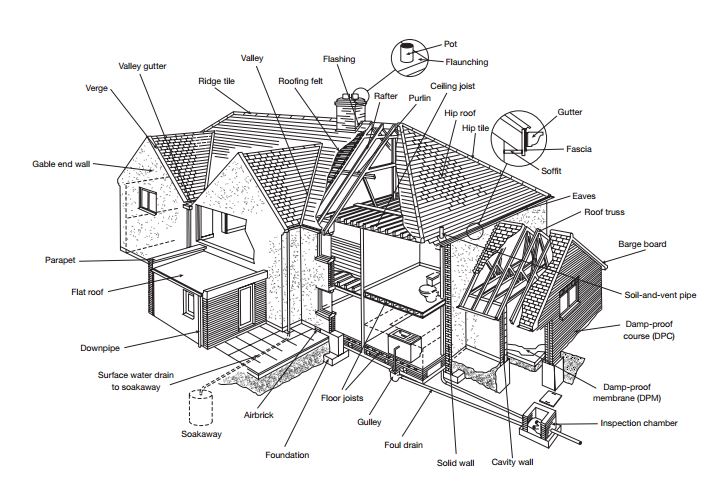

Typical house construction

Typical house construction