Asbestos in Buildings

Asbestos in Buildings

Buildings constructed between 1950 and 1980's may have had some form of asbestos incorporated within the construction.

Usage in Buildings.

The areas of Asbestos use may be found include: Roof and Wall cladding - Flue pipes -Boiler cupboards - Insulating boards and Sound proofing panels-Heating pipe -Thermoplastic and vinyl floor tiles (often referred to as Marley Tiles) - Guttering and downpipes - soffits - Internal textured decorative coatings.

Should Asbestos wall or ceiling sheeting in good condition be identified then it is permissible to coat these surfaces with a water based product.

The removal of any dust dirt or surface contaminants should only be removed by approved contractors.

Health and Safety recommendations should be strictly followed by wearing full PPE including:

Full body overalls including head protection precautions, gloves, face covering, eye goggles and shoe coverings.

If loose particles are found under no circumstances should attempts be made to sweep or hoover up any loose material.

Generally three types were used and referred to as White, Blue and Brown.

As it is not always easy to identify an asbestos surface so if in doubt it is always best to leave and call in the experts.

Paint Suppliers: http://www.thermoguarduk.com/portfolio-items/asbestos-encapsulating-coat/

Training Providers: IATP> Independent Asbestos Training Providers https://www.iatp.org.uk/

Asbestos Removal Contractors Association: https://www.arca.org.uk/

Asbestos Testing and Consultancy Association: https://www.atac.org.uk/asbestos-testing-and-consultancy-association

Flooring Problems

Floor Paint Problems

Failure of paint coatings onto concrete flooring can be caused by a number of reasons but predominately is due to moisture within the subflooring, applying paints over a poorly prepared surface. Another common cause is when parking vehicles onto the coated surface before the tyres had cooled down. This causing fusion between the hot rubber and the paint coating which causes de-detached from the concrete surface when the vehicle is moved.

Also see 'Don't let flooring problems trip you up' in News.

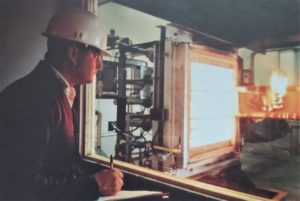

BS 476 Guidance on Performance of Paint Finishes in Standard Tests

Guidance on Performance of Paint finishes in Standard Tests

Guidance on Performance of Paint finishes in Standard Tests

- Paint systems cannot be tested in isolation; they must be tested as they will be used in practice applied to a representative substrate.

- Test results can vary dependent upon the nature of the substrate to which they are applied. If paint is applied to a timber substrate, for example, it is likely to give a worse performance than if it is applied to a plasterboard substrate.

- It is not possible to generalise substrates as ‘combustible’ or ‘non-combustible’. A test result on a steel substrate, for example, may be worse than on a plasterboard substrate because Delamination of the coating from the steel occurs. Conversely a better result may be obtained on the steel substrate because it has different thermal characteristics than the plasterboard. Generalisations are dangerous.

Small differences in substrates can significantly affect the test results; the thermal conductivity, specific heat and density of the substrate all influence the test performance. A thinner steel substrate, for example, could give worse results than a slightly thicker steel substrate. With combustible substrates thicker substrates tend to give an improved performance during the early stages of the test due to increased thermal capacity) but poorer performances during

- the later stages due to additional fuel availability.

- The preparation of the substrate (e.g. cleaning, primer, undercoat systems) can affect the test results. The degree of adhesion of the coating system under the test conditions can be very important.

- The thickness of the coatings can be significant. In general the thicker the coatings the worse the result, but again generalisations can be dangerous.

- Apparently minor variations such as colour, method of application, time between application of coats and temperature/humidity conditions during the application process can all affect the test results.The development of a meaningful test programme to give the widest possible information on the paint system is therefore vital. Control of the application process is also important to ensure that the coating systems applied in practice are as similar as possible to the situation which was tested.

- Previously Painted SurfacesIt is not possible to confidently predict the spread of flame and heat release properties of coatings applied to previously painted surfaces. The existing paint finishes may be old and the effectiveness of their adhesion to the substrate or between coatings may be poor. In general, existing gloss paint systems tend to be the greatest problem and this is influenced by miniscule deposits of dirt which are difficult to remove, even by thorough washing. These cause trapped air layers which can lead to insulation/delamination problems. The combination of gloss and emulsion systems can also lead to poor performance, underlying emulsion coatings acting as an insulating layer. On the other hand it is possible that the properties of the old paints may have improved with ageing. Some paint manufacturers have conducted series of tests to investigate the properties of multi-coat systems, usually with modern paint formulations and these are usually accepted by specifiers as satisfactory evidence. The only way, however, is to remove all previous coatings and apply new systems to the stripped substrate.

Health and Safety Executive (HSE) Guidance

| PPE (Personal Protective Equipment) |  |

|---|---|

| https://www.hse.gov.uk/toolbox/ppe.htm | |

| Fire Safety |  |

| https://www.hse.gov.uk/construction/safetytopics/processfire.htm | |

| Riddor (Report injuries, diseases and dangerous occurrences) | |

| https://www.hse.gov.uk/riddor/index.htm | |

| Manual Handling | |

| https://www.hse.gov.uk/simple-health-safety/training/index.htm | |

| Asbestos |  |

| https://www.hse.gov.uk/asbestos/index.htm | |

| Working at Height |  |

| https://www.hse.gov.uk/construction/safetytopics/assess.htm |

Carbonation of Concrete

Carbonation of concrete.

Carbonation of concrete.

Carbonation of concrete is caused when moisture penetrates through porous areas of the structure allowing carbon dioxide to react with calcium hydroxide in the cement. (calcium carbonate).

When mixed with water the calcium carbonate forms a paste and can lead to corrosion (rust) of the steel reinforcing bars (Rebars).

As the corrosion builds up the the swelling can cause the concrete to fracture and ultimately breakaway.

For minor works the following solution may be considered but for any major works a structural engineer should be consulted.

Solution.

Where carbonation has occurred, all defective concrete should be removed and the exposed steel bars should be cleaned to remove all corrosion; followed by priming the steelwork with an anticorrosive primer.

All defective areas of concrete should then be made good as required and allowed to dry.

Painting.

An anti-carbonation coating should be applied in accordance with the manufacturer's instructions.

Suppliers of anti-carbonation coatings include.

Andura Coatings. https://www.andura.com/contact

New Guard Coatings Limited. https://newguardcoatings.com

Dulux. https://www.duluxtradepaintexpert.co.uk

Johnstones Paints.https://www.johnstonespaint.com/

Hardwood - Varnishes and Translucent Wood Finishes

Hardwood New

Varnishes and Translucent Stain Finishes.

While hardwoods are often allowed to weather naturally others prefer to treat the wood with either varnish or translucent wood stains.

Preparation.

All surface contaminants should by the most appropriate means followed by sanding down with suitable grade of glass- sand or garnet paper to prove a smooth surface.

Any visible resin around knots or sap residue should be removed and the surface wiped over with methylated spirit. When dry two thin coats of a white shellac

knotting.

Clear shellac should be used over any knots or sap residue.

All making good should be carried out with an appropriate wood filler and tinted to match the surrounding surface and sanded down.

Painting.

Apply one sealer coat and two full coats of the selected coating following the manufactures instructions

Note: If a normal coloured shellac knotting is used the shade will mirror through any subsequent clear or tinted finish.

Linseed oil putty should not be used for glazing or filling. Alkyd based sealants are recommended

Any discolouration of the bare wood due to weathering or water attack can be difficult to remove but treating the area with Oxalic Acid may remove the discolouration.

See: Problems and remedies Flaking of Stained wood finishes.

For further product information:

https://www.liberon.co.uk/product/palette-wood-dye

https://www.zinsseruk.com/product

Graining Tool Box

For further information on Graining tools and equipment:

H S Handover Ltd. Tel: 0207 2415877 - www.handover.co.uk

Gilding Tool Box

For full information on Tools and Equipment contact: A S Handover Ltd at: http.//www.handover.co.uk

Corroded Aluminum

Aluminium Corrosion

Cause

Although naturally resistant to corrosion when untreated aluminium is exposed to the external weathering a thin layer of oxide forms on the surface and enhances the resistance to corrosion.

However, this thin layer of oxide while being insoluble in water and resistant to some chemicals, it does not prevent the aluminium from loosing its glossy appearance and becoming dull.

Corrosion attack can occur if aluminium comes in contact substrates such as new concrete and other building components which have a alkaline content. Additionally, contact with other metals such as copper, lead, iron and copper naphthenate used as a wood preservative should also be avoided. Contact with sulphuric and hydrochloric acids along with chlorinated based solvents should also be avoided.

Remedy

See: Specification for Galvanised steel.