Site Testing Equipment

Site Testing Equipment. Under Construction.

Site Testing Equipment. Under Construction.

Site testing equipment should be appropriate for the work in hand and can vary from a standard moisture meter to those require to check the paint system used, film thickness and adhesion.

Pinhole detector see: Glossary of Terms Decorators. https://www.elcometer.com/coatings-inspection/all-coatings-inspection/pinhole-porosity-detection.html

Dry Film Thickness Gauge see:: Glossary of Terms Decorators. https://www.elcometer.com/en/coatings-inspection/all-coatings-inspection/dry-film-thickness/digital/elcometer-456-separate-coating-thickness-gauge.html

MDF Adhesion of applied Coatings

MDF Adhesion Problems

Cause

Paraffin wax is often used in the manufacture of MDF to improve the water resistant properties.

Some of the wax treatment can remain on the surface and can affect the adhesion of primer coating when applied without any form of preparation.

Lightly sand down and wipe over with Methylated Sprit and allow to dry.

Check that the selected paint manufactures priming coat is suitable and if necessary apply to a prepared to check the adhesion.

Site Induction

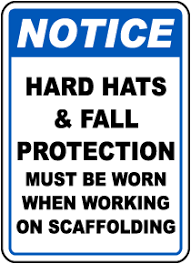

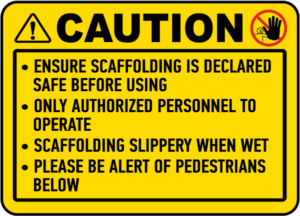

Site Induction, is carried out to ensure all personnel working on the the site is familiar with the Health and Safety requirements.

Health and Safety Induction Checklist

Induction & Method signing register SITE example

Risk Assessment Manual Handling

Click on link

ESK RISK ASSESSMENT

| OPERATION/PROCESS

MANUAL HANDLING |

DATE:

|

No 3 | |||||

| LOCATION

|

|||||||

| EQUIPMENT USED

Ladders, step ladders, podiums, paint and materials |

CAN TASK BE ELIMINATED? | Yes

|

No

X |

||||

| RISK PRIOR TO CONTROLS | |||||||

| HAZARDS IDENTIFIED | Low | Med | High | ||||

| Sprains & Strains and crushed limbs | X | ||||||

| EXPOSED PERSONS

Site operatives |

TOTAL NUMBERS AFFECTED | ||||||

| FREQUENCY OF EXPOSURE

Daily/Low |

DURATION OF EXPOSURE

Low/minimal over an 8 hour working day. |

||||||

| CONTROL MEASURES ALREADY IN PLACE

1. Operatives are experienced in carrying paint and equipment on a regular basis as part of their daily work and are aware of the dangers of moving and lifting. Maximum lift of 10kgs 2. HSE information on manual handling provided to operative and regular toolbox talks 3. All operatives are told to seek assistance when carrying ladders, stepladders and podiums |

EXTENT TO WHICH THEY CONTROL RISK

1. Operatives are aware of correct lifting techniques. 2. Toolbox talks carried out to reiterate manual handling procedures. 3. To avoid injury to operative. |

||||||

| ADDITIONAL MEASURES REQUIRED

Review for each task as required throughout the contract. Trainees to be supervised |

ACTION BY

Management, supervisors & operatives. |

BY WHEN

Prior to contract start date and on-going throughout contract. |

|||||

| STATEMENT OF RESIDUAL RISKS

When the detailed control measures in place are adhered to, the risks above should be reduced to an acceptable level. |

|||||||

| ADDITIONAL REQUIREMENTS FOR VULNERABLE GROUPS

Ensure that physical capabilities are taken into account when allocating works. |

|||||||

| MONITORING RESULTS

Monitoring is required to ensure that the control remain effective. |

|||||||

| ASSESSOR – NAME

|

POSITION

Director |

REVIEW DATE

01.06.21 |

LAST REVISED

01.06.20 |

||||

Risk assessment Manual Handling