Risk Assessment Manual Handling

Click on link

ESK RISK ASSESSMENT

| OPERATION/PROCESS

MANUAL HANDLING |

DATE:

|

No 3 | |||||

| LOCATION

|

|||||||

| EQUIPMENT USED

Ladders, step ladders, podiums, paint and materials |

CAN TASK BE ELIMINATED? | Yes

|

No

X |

||||

| RISK PRIOR TO CONTROLS | |||||||

| HAZARDS IDENTIFIED | Low | Med | High | ||||

| Sprains & Strains and crushed limbs | X | ||||||

| EXPOSED PERSONS

Site operatives |

TOTAL NUMBERS AFFECTED | ||||||

| FREQUENCY OF EXPOSURE

Daily/Low |

DURATION OF EXPOSURE

Low/minimal over an 8 hour working day. |

||||||

| CONTROL MEASURES ALREADY IN PLACE

1. Operatives are experienced in carrying paint and equipment on a regular basis as part of their daily work and are aware of the dangers of moving and lifting. Maximum lift of 10kgs 2. HSE information on manual handling provided to operative and regular toolbox talks 3. All operatives are told to seek assistance when carrying ladders, stepladders and podiums |

EXTENT TO WHICH THEY CONTROL RISK

1. Operatives are aware of correct lifting techniques. 2. Toolbox talks carried out to reiterate manual handling procedures. 3. To avoid injury to operative. |

||||||

| ADDITIONAL MEASURES REQUIRED

Review for each task as required throughout the contract. Trainees to be supervised |

ACTION BY

Management, supervisors & operatives. |

BY WHEN

Prior to contract start date and on-going throughout contract. |

|||||

| STATEMENT OF RESIDUAL RISKS

When the detailed control measures in place are adhered to, the risks above should be reduced to an acceptable level. |

|||||||

| ADDITIONAL REQUIREMENTS FOR VULNERABLE GROUPS

Ensure that physical capabilities are taken into account when allocating works. |

|||||||

| MONITORING RESULTS

Monitoring is required to ensure that the control remain effective. |

|||||||

| ASSESSOR – NAME

|

POSITION

Director |

REVIEW DATE

01.06.21 |

LAST REVISED

01.06.20 |

||||

Risk assessment Manual Handling

Concrete -Screed Flooring - New/Existing

Concrete Flooring New

When new concrete flooring is laid, it is occasionally finished off by polishing to produce the smooth seamless floor.

In instances where a coating is required, then the moisture content of the concrete substrate should be no higher than 5% and specific moisture meter instruments are available for checking purposes.

Because a polished floor can leave residual cementitious material on the surface, this should be removed by washing with hydrochloric acid.

Following the preparatory work, then numerous types of floor coatings can be applied ranging from low film build water-based materials to high build two pack polyurethane or epoxy coatings.

Concrete Flooring Existing

Existing floorings could have been exposed to different types of usage and the condition may warrant additional preparation before being refurbished. In preparing existing, textured flooring not matter how fine it may be that mechanical equipment should be considered, such as scrabbling machine or a light sandblast.

https://newguardcoatings.com/independent-inspection/

1-2-3-4 reasons for painting

The reason for painting is based on 4 principals: Preservation, Decoration, Sanitation and Identification.

Preservation.

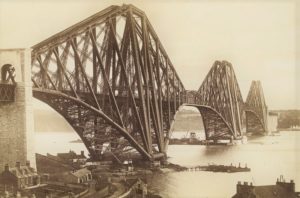

The Forth Bridge being constructed in 1898. The latest painting project completed in 2013 and guaranteed for 25 years.

Decoration.

Ranging from normal interior and exterior painting to skills including wallpaper hanging, heraldry and gilding. See under 'And much more' Advance decorating skills.

Sanitation.

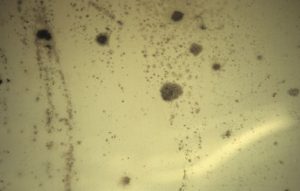

Protection against mould and algae problems

Identification.

Specific colours are used for health and safety purposes.

Wide Width Wallcoverings

Wide Width Wall Coverings

Toolbox

For further information on wide width wallcoverings see: https://www.muraspec.com/technical.php

Wide Width Wall Coverings

Wide Width Wall Coverings

These wall coverings are wider than normal wallpaper width of 53cm and be as wide as 138 cm depending on manufacture.

Coverings such as Cloth backed ,Silk, Flock, Grasscloth and Fiberglass are available.

Surface preparation prior to hanging is on the same lines as for standard wallpapers and should be free of all surface irregularities and contaminates.

The method of hanging wide width coverings generally requires the adhesive to be applied to the wall surface and not the reverse side of the coverings.

In all case the manufacturer's details on size and application should be obtained and followed for estimating purposes.

See: Tools Box in Tools and Equipment.

For more information:

Muraspec wallcoverings. https://www.muraspec.com/

https://www.grahambrown.com/uk/wallpaper/grasscloth

For application technique : https://www.youtube.com/watch?v=QHKzgskqtFs https://www.youtube.com/watch?v=9l7nNJLJlJY