Render / Rendering

Rendering on the exterior walls of building is generally used as an alternative to brick or concrete blocks.

Note. While dry render is paintable care should be taken as to the quality and nature of the work.

If in doubt regarding the condition and product suitability of a coatings to applied advice from the manufacture should be obtained.

Blistering/Osmosis Exterior Rendered Walls

Blistering (Osmosis) of paint coatings applied to wall surfaces.

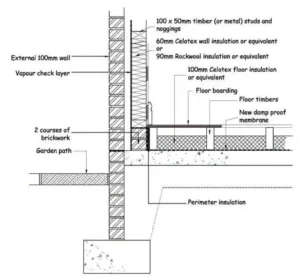

This this problem can be found on both interior and exterior wall surfaces is is associated with liquid water or water/moister water coming in contact contact within the building fabric.

Internally it can due to breakdown within the plumbing system. Externally by a fault within the build construction such as poor damp proofing, water from internal pipework wetting into the exterior building fabric.

Water from the ground or a faulty damp proof course (DPC) moves up through a porous substrate (like brickwork), through any semi-permeable membrane i.e. render, and the hydro moisture pressure builds, forming fluid-filled areas (water) under and within the underlying the porous substrate such as render. These wet areas can cause the underlying surface i.e. sand : cement to crumble with blisters forming on the exterior of the wall painted surface.

Exterior paint finishings although protecting the painted substrate from the ingress of moisture from external water i.e. rain /washing down they are not permeable to water are moisture vapour. Consequently surface blistering occurs and can due to the underlying weak substrate, render, can fail.

When problems of this nature are experienced to primary operations should be carried out: 1: gently remove the affected are exposing the underlying surface. 2: examine the reverse sire to the sample removed. 3: check with an approved moisture meter the moisture content of the area removed in relation the overall general area to establish the the

This can occur with any coating where moisture is trapped behind it, but it is a common issue with older properties lacking a functional DPC

See. Osmosis

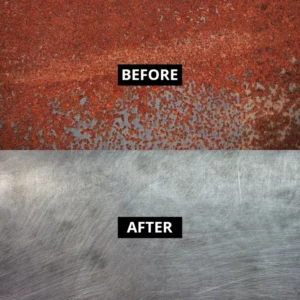

Hydrochloric Acid

Hydrochloric Acid Acid is used to etch newly laid cementitious before painting.

It is also available to remove unwanted mortar splashes from bricks.

Hydrochloric acid and can also be applied

as a rust remover.

as a rust remover.

See Phosphoric Acid.

It is inportantant that the all H&S and Product details are followed as stated on the manufactures data sheets before use.

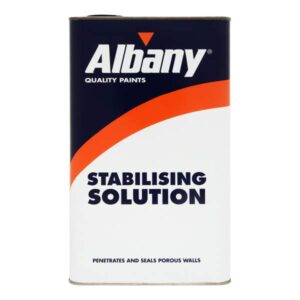

Stabilising Solution:

An oil based paint used for consolidating powdery surfaces and coating such as limewash /distemper, prior to applying water or oil based coatings.

Osmosis

Osmosis

Cause

Osmosis is generally associated to areas where fibreglass and polyester resins have been uses.

This system, used in the production of modern yachts is where Osmosis is most likely to occur but also

precast structures such as GRP Swimming pools.

Osmosis

GRP Swimming Pool due to small pin holes left in the laying of the glass fibre weave. This same type of problem can occur in wall surfaces when moisture pressure from the reversed side of the structure has not been sealed and allowed moister vaper to enter to bare untreated substrate.

This is related to the external cavity walls where the air movement within the cavity maybe restricted.

Initially small blisters become visible and over a period of time increase in size.

For example this problem can also occur where GRP and Cementous concrete swimming pools have been used and when in situ the revers side has not been sealed.

The water pressure present in the surround ground level can cause moister ingress into the substrate and blisters of the paint coatings occurs

Remedies.

Before remedial work is carried out the and retreated the moisture content should be below 12%

For further information on Osmosis: https://www.yachtingnews.com/osmosis

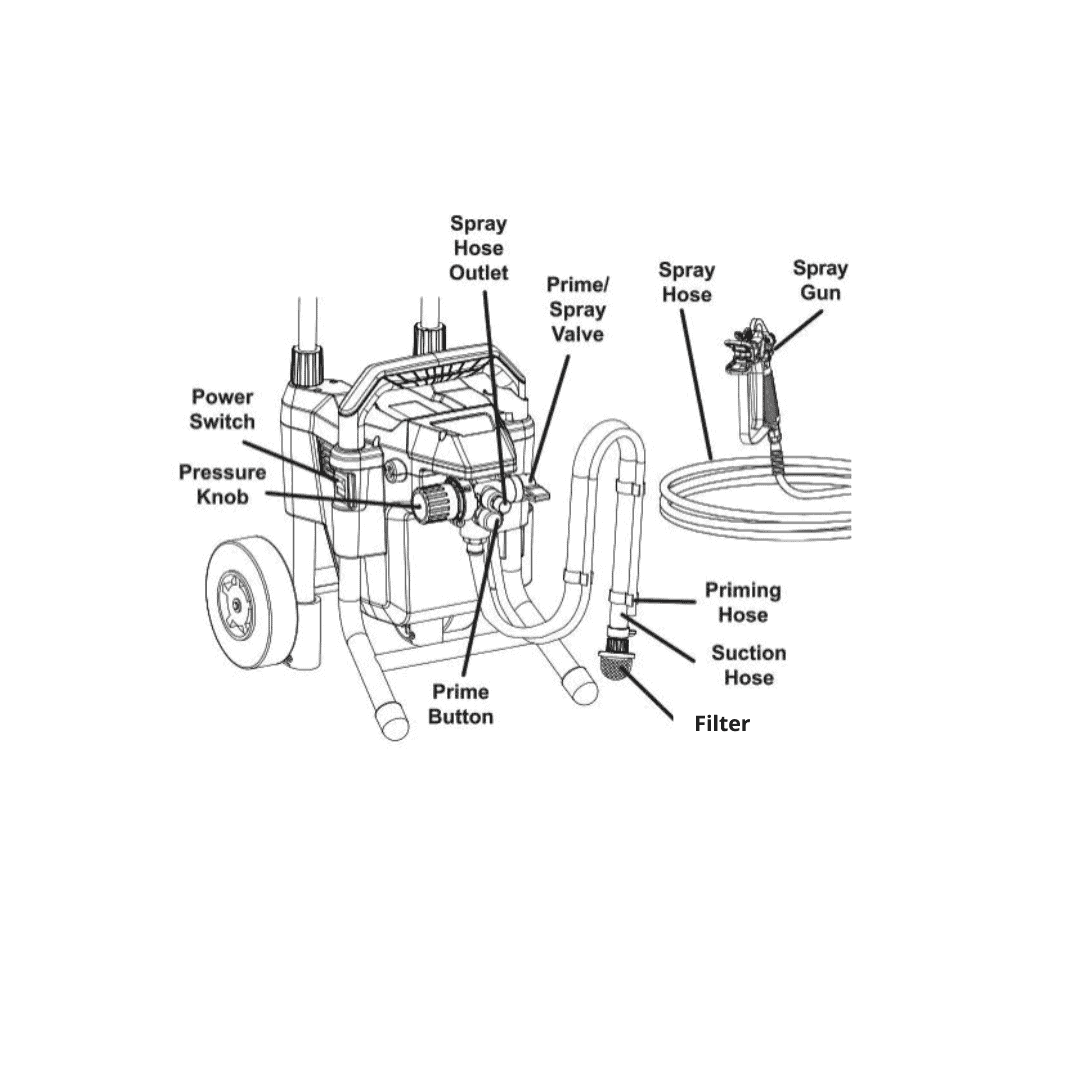

Spraying Airless Common Problems and Remedies

Airless Spraying and Equipment

Common Problem and Remedies

Airless spray equipment is based on an electric motor (petrol driven motors are available) and hydraulic pump driven system to delivers paint/coating products under very high pressure up to 3000 pounds per square inch (PSI) to the spray gun.

Motor unit does not run or stops.

a) Check the origin of the power supply and all connecting cables followed by pressing the reset button.

b) Check the fluid control settings.

c) Confirm the switch in the ON position and the pressure control regulator is correctly set to maximum pressure setting.

Cannot Prime

a) Pump inlet suction filter blocked. Remove and clean.

b) Air in the hose or pump. Seal or replace.

c) Valve set on prime. Turn key onto spray.

d) Air in pump or hose or inlet filter blocked.

e) Check the piston packing has not dried out and the ball valve is free.

Material too viscous.

a) Confirm manufactures’ data for product viscosity and thinning ratios.

b) Check syphon tube for blockages or air leaks.

Pressure not being maintained

Check:

a) Filter to pump inlet – clean.

b) Pressure setting too low - increase

c) Air in either pump or hose – with spray gun trigger held open for 10-15 seconds to clear any air.

d) Spray tip too large.

Irregular and poor spray pattern

a) Size of spray gun tip incorrect- change tip.

b) Incorrect pressure – Adjust as necessary.

c) Material too viscous – adjust with correct thinner to manufactures recommendations.

Cannot shut off material supply at gun.

a) Thoroughly clean spray gun with product thinner/solvent.

b) Needle stop nut too tight- loosen slightly.

c) Needle worn – replace.

Spray gun will not operate.

a) Safety trigger on.

b) Inline filter blocked – Clean or replace - Adjustable tip blocked.

Spray pattern has Tails and strips:

a) Pressure too low – increase pressure.

b) Paint too viscous – see manufactures data for thinning.

c) Tip too wide – Adjust to reduce pattern size.

d) Spray tip worn – Replace.

Pressure does not increase when paint is drawn up:

a) Bypass valve in prime position -Turn valve to spray.

b) Air in hydraulic system – Bleed system.

c) Pressure valve incorrectly adjusted or worn sprat tip.

Spray pattern uneven:

a) Blocked or worn spray tip – replace tip.

Spray tip keeps clogging:

a) Contaminated material – Check inline gun filter.

b) Dry paint in spray tip - clean.

Pump not drawing up material.

a) Suction tube either loose or damaged drawing in air.

b) Suction tube not immersed in the material.

c) Suction Filter blocked.

Pump primes but no pressure.

a) Suction filter blocked – remove clean or replace.

b) Prime switch not set to spray.

Spray repair and service companies

Trade Spray Services 01686829001 tradepaintservices.co.uk

Spray Plant ltd 01133233117 [email protected]