Airless Spraying and Equipment

Common Problem and Remedies

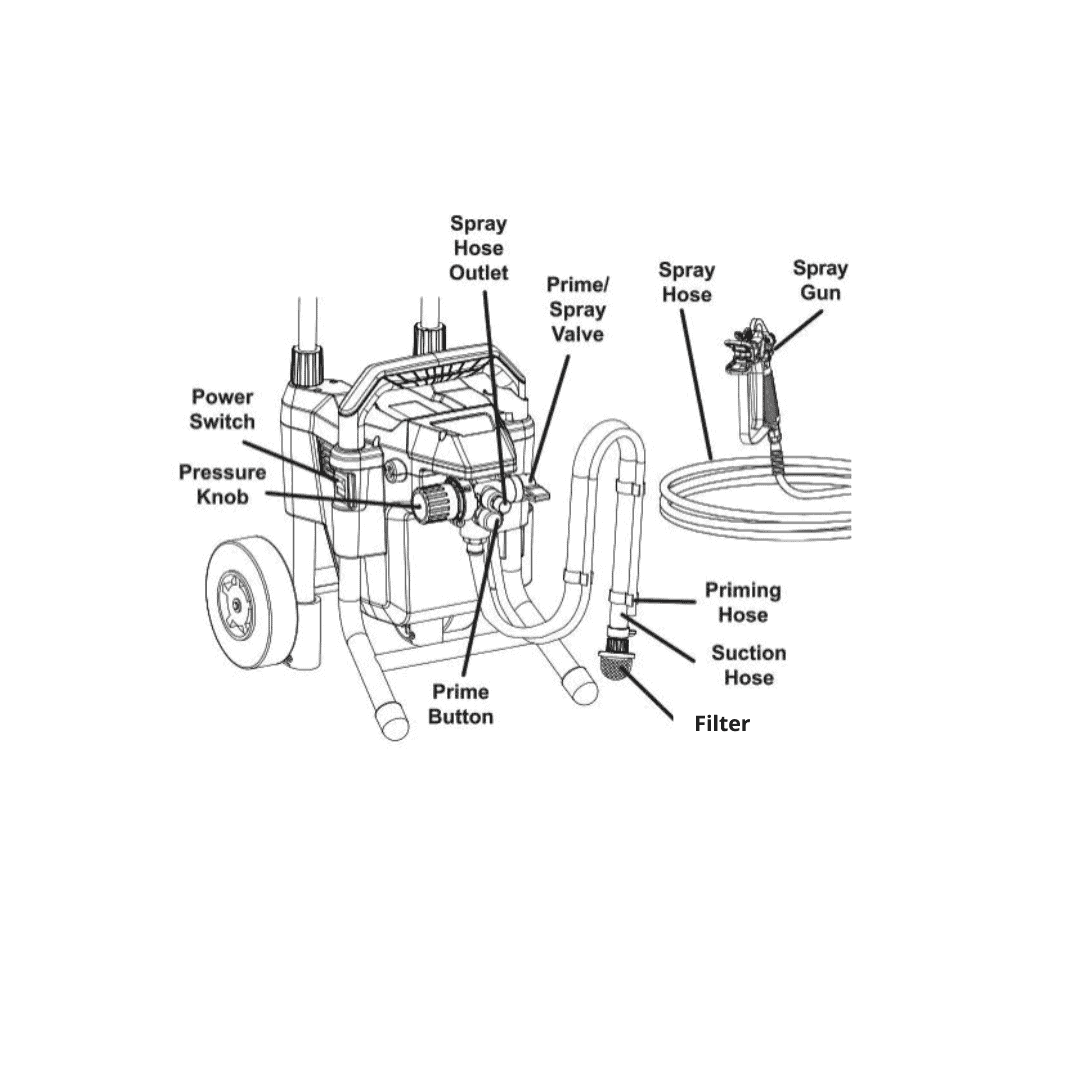

Airless spray equipment is based on an electric motor (petrol driven motors are available) and hydraulic pump driven system to delivers paint/coating products under very high pressure up to 3000 pounds per square inch (PSI) to the spray gun.

Motor unit does not run or stops.

a) Check the origin of the power supply and all connecting cables followed by pressing the reset button.

b) Check the fluid control settings.

c) Confirm the switch in the ON position and the pressure control regulator is correctly set to maximum pressure setting.

Cannot Prime

a) Pump inlet suction filter blocked. Remove and clean.

b) Air in the hose or pump. Seal or replace.

c) Valve set on prime. Turn key onto spray.

d) Air in pump or hose or inlet filter blocked.

e) Check the piston packing has not dried out and the ball valve is free.

Material too viscous.

a) Confirm manufactures’ data for product viscosity and thinning ratios.

b) Check syphon tube for blockages or air leaks.

Pressure not being maintained

Check:

a) Filter to pump inlet – clean.

b) Pressure setting too low – increase

c) Air in either pump or hose – with spray gun trigger held open for 10-15 seconds to clear any air.

d) Spray tip too large.

Irregular and poor spray pattern

a) Size of spray gun tip incorrect- change tip.

b) Incorrect pressure – Adjust as necessary.

c) Material too viscous – adjust with correct thinner to manufactures recommendations.

Cannot shut off material supply at gun.

a) Thoroughly clean spray gun with product thinner/solvent.

b) Needle stop nut too tight- loosen slightly.

c) Needle worn – replace.

Spray gun will not operate.

a) Safety trigger on.

b) Inline filter blocked – Clean or replace – Adjustable tip blocked.

Spray pattern has Tails and strips:

a) Pressure too low – increase pressure.

b) Paint too viscous – see manufactures data for thinning.

c) Tip too wide – Adjust to reduce pattern size.

d) Spray tip worn – Replace.

Pressure does not increase when paint is drawn up:

a) Bypass valve in prime position -Turn valve to spray.

b) Air in hydraulic system – Bleed system.

c) Pressure valve incorrectly adjusted or worn sprat tip.

Spray pattern uneven:

a) Blocked or worn spray tip – replace tip.

Spray tip keeps clogging:

a) Contaminated material – Check inline gun filter.

b) Dry paint in spray tip – clean.

Pump not drawing up material.

a) Suction tube either loose or damaged drawing in air.

b) Suction tube not immersed in the material.

c) Suction Filter blocked.

Pump primes but no pressure.

a) Suction filter blocked – remove clean or replace.

b) Prime switch not set to spray.

Spray repair and service companies

Trade Spray Services 01686829001 tradepaintservices.co.uk

Spray Plant ltd 01133233117 [email protected]