Decorative Textured Finishes

Preparation.

General.

New plasterboard.

Ensure all surfaces are are clean, dry and free from flaking/defective material, oil and grease.

For previously oil painted gloss surfaces, lightly abrade to provide a key, wash down using a damp sponge remove loose contaminates and allow to dry.

Any surfaces which are powdery in nature apply one coat of stabilising solution applied in accordance with manufactures instructions. Note : When dry any areas which display a gloss finish should be lightly abraded before progressing.

Surfaces of high porosity apply one coat of General Purpose Sealer in accordance with manufactures instructions.

Textured Base coats and Finishes should be mixed and applied in accordance with manufactures instructions.

For further information and product advice: https://www.artexltd.com

Decorative Textured Finishes (Artex®)

Toolbox for Decorative textured finishes.

Notes: Artex® is a registered brand name and is generally referred to within the building and decorating trade to describe textured finishes.

For further information : https://www.artexltd.com/about-artex

Check manufacturer's advice on any Personal Protective Equipment needed.

Wet wood Rot

Wet Wood Rot

Cause

A moisture content in wood in the region of 40% + is the point when the timber fibres begin to degrade. The major cause is poor maintenance, allowing moisture to enter the wood when exposed to the elements or for example, internally, where the sealant/putty seal between the glass and window frame has failed and condensation occurs, the water is then absorbed into the wood, affecting the cross rails, cill and styles.

Timber affected by Wet Rot will feel soft and spongy (even through a coat of paint) and look darker than surrounding timber. When dry, the timber will easily crack and crumble into fine particles. It can also be susceptible to shrinkage.

Some types of Wet Rot cause the wood to bleach. This is common in doors and window frames.

If the paint film is damaged and not treated this can increase the risk of wet rot. If you suspect wet rot and the paint film is not damaged, push a thin bladed knife into the painted timber. The blade should stop after a short distance. If it goes in up to the handle, it is almost certainly a sign of rot behind the paint coatings.

Remedy

Wet Rot is easier to deal with than Dry Rot, as the cause is restricted to where moisture has entered the wood. Depending on the degree of Wet Rot, it may be necessary to remove and replace a section or the item, e.g. window/door. Where the defect is restricted to one area then it may be possible for a qualified joiner to cut it out and replace with new wood. Alternatively, a special two component wood repair system can be used by following the manufacturer’s instructions. Painting can then be carried out in accordance with the proposed specification.

For further information and specific advice contact: www.repair-care.co.uk windowcaresystemsang (Video)

Spraying HVLP (high volume low pressure)

HVLP (high volume low pressure). The advantage of HVLP spray units is that they operate on a lower pressure, therefore, can be used within a domestic area as little overspray is created.

HVLP (high volume low pressure). The advantage of HVLP spray units is that they operate on a lower pressure, therefore, can be used within a domestic area as little overspray is created.

Ideal for spraying decorative paints and in particular multi-colour finishes.

As overspray is minimal, the use of this type of spray unit is very cost effective as the time spent on masking and sheeting is reduced.

Spray equipment available from companies such as: Wagner-group Ltd.

https://www.wagner-group.com/uk/contractor/products-and-accessories/product/finecoat-9900-plus/

Spraying Airless

Airless Spray

Today’s High Efficiency Airless (HEA) spray technology makes the application of paint more versatile and suitable for both exterior and internal projects due to a lower pump pressure being required. This reduction means the degree of overspray is reduced up to 50% which results in less masking up being necessary. The spray patterns can be varied therefore smaller areas and cutting in can be sprayed with ease.

Oil and water based paints can be applied by airless spray and paint manufactures data sheets will advise as to which set up and tip size is required for the best results.

The advantage of HEA is its versatility of use for either interior or exterior work as well as reduction in masking up and speed of application compared to brush or roller application.

Airless Spray General.

Airless spray pumps are available in a range of different pump sizes/ratios depending on the material to be used. The units available will accommodate products from standard emulsion paints to high build and thixotropic products. Therefore advice should be sought to establish which would be the appropriate for the project.

Spray equipment available from companies such as:

Wagner-group Limited - https://www.wagner-group.com/uk/our-company/

British Standards and other Regulatory Standards

British Standards. https://shop.bsigroup.com/

BS 381C A range of colours for special purposes and identification including those for use on military vehicles.

BS 5252 Framework for colour co-ordination for building purposes

BS 5493 Protective Coating of iron and steel structures against corrosion code of practice. (BS EN ISO 14713)

BS 8000-0:2014 Workmanship on building sites. Code of practice for plastering and rendering Supersedes Part 10

BS 4800 2011 Colours for Building paints. 117 colours taken from BS 5252

BS 8000 -12 Workmanship on Building Sites Code of practice for decorative wall coverings and painting.

BS 8000-7:1990 Workmanship on building sites. Code of practice for glazing.

BS 8000-5:1990. Workmanship on building sites. Code of practice for carpentry, joinery and general fixings

BS 1710 Basic Identification Colours for Pipelines

BS 6150 Painting of buildings -Code of practice 2019

BS 6150: 2006 Painting of Buildings - Code of practice (+A1:2014)

BS BS476 part 6 2009 Fire propagation Class O.

BS476 part7 1997 Flame retardant coatings surface spread of flame. Class 1.

M60 Painting/Clear Finishes National Building Specification Ltd. https://www.thenbs.com/

M61 M61 Intumescent coatings for fire protection of steelwork

HASAWA Health and Safety at Work Act https://www.hse.gov.uk/legislation/hswa.htm

HSE Health and Safety Executive https://www.hse.gov.uk/

Paint Research Association www.pra-world.com

Colour Standards

How does one describe colour?

Your perception and interpretation of colour is highly subjective and quite often differs from one person to person.

As a result it is difficult to communicate a particular colour to someone without some reference to an agreed standard. A recognised colour system within the UK was the introduction of BS 2660 Colours for building and decorative paints in 1955. This colour range consisted of 100 colours with cross reference to the Munsell range.

Prior to this manufactures had their own colour systems which linked to the British Standards and Munsell Tree colour notations.

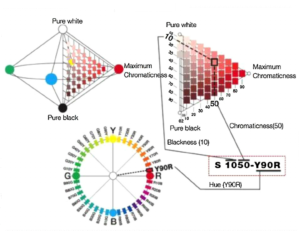

Currently two colour systems are referred to enable colour to which enable colour to be interpret by using notations based on three properties. Hue, Value and Chroma. Hue denotes the basic colour, Value measures the lightness and darkness of the Hue, Chroma relates to the greyness of colour.

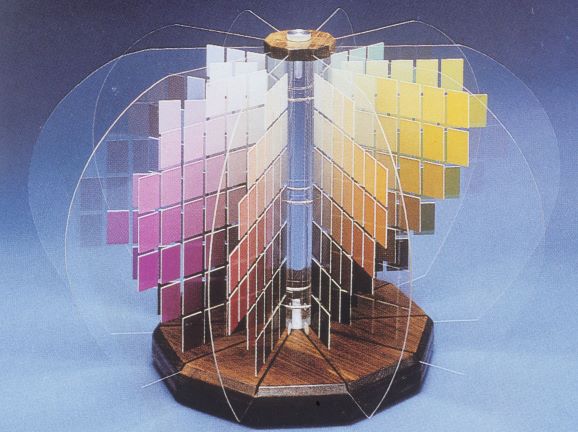

The Munsell tree illustrated operates on three principals. The circumference relates to the Hue which is a Colour Circle base on primary, secondary and tertiary colours. Value is the centre vertical pole of the tree which is divided into eleven divisions with white expressed as 10 and black 0.

Therefore the colour scale between the two is represented in the form of greys from light to dark. Chroma is measured on a horizontal scale from the grey tone outwards to the pure hue.

The Natural Colour System(NCS) operates in a similar way to the Munsell tree by taking Hue, Chroma, Value but in this instance separating the colour byway of a colour circle and triangle as illustrated below in favourites.

The Munsell colour tree was first introduced in 1905 by Albert Munsell and the colour offering was adopted by most manufactures as a cross reference to their own colour assortment. In 1955 British Standards introduced BS2660 Colours for Building and Decorative Paints which still had the cross reference to the Munsell system.

In 1986 BS 2660 was superseded by BS 4800 ( current standard 2011) which is taken from the British Standards 5252 Framework for Colour Co-ordination for Building Purposes.

In1997 The Scandinavian Colour Institute introduced the NCS range of over 1200 colours and was adopted by one of the UK larges paint company which lead to other manufactures producing their own colour section. It is for this reason that leading manufactures now offer an extensive colour of colours and with the use of a spectrophotometer it is possible for any dry colour sample can be matched and mixed at the point of sale.

How is Oil Paint Made

Paint in one form or another has been used for centuries for decoration, preservation of surfaces, sanitation and identification purposes.

Paint in one form or another has been used for centuries for decoration, preservation of surfaces, sanitation and identification purposes.

The most commonly used paints within the building industry are either oil or water based.

Oil Paints.

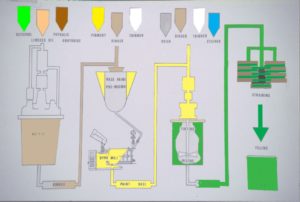

Oil based paints are formulated around four main ingredients:

For decorative paints modified natural oils form the basis of the Binder which is referred to as an Alkyd Resin or Vehicle. Binders for industrial coating are based on epoxy and polyurethane resins.

The Oils used can be Linseed, Tung or Rapeseed. This modified clear material is akin to a varnish in appearance further are added to provide a hard durable finish.

Pigments/Extenders include Titanium Dioxide (White) / Chalk / China Clay. These are used to provide the opacity/ covering power required.

Thinners/Solvents such White spirit/Xylol –Xylene are added which adjusts the thickness/ viscosity of the product.

Additives include special Driers which assist in the overall drying time of the oi based paint. Anti-skinning and thickening agents

can also be added.

Computer Controlled Manufacturing

|

|

|

|

|

|

Traditional Manufacturing

Spray Painting Why Not?

Spraying Painting- why not?

Spray painting is not difficult; pull the trigger, paint flows, release the trigger, paint stops.

Traditional painting methods by brush and roller can be time consuming but today even though masking up of areas may be necessary, spray painting is more efficient.

Included in today’s range of spray equipment are low pressure units which reduce the amount of masking up needed.

While training is required, there are academies where the basic principles of spraying can be mastered within the day.

Once mastered the benefits associated with spray application including speed and cost savings are readily appreciated.

See range of spray units under: And much more : Advanced Decorating Skills

The range of equipment available for the domestic and industrial applications readily available from manufacturers and nationwide decorators merchants such as:

https://www.wagnerspraytech.com

https://www.brewers.co.uk/products/spray-painting

Paint Like a Pro. https://www.youtube.com/watch?v=RNRay1oMHfU&feature=emb_rel_end