Galvanized Steel

General.

General.

New Galvanised steel is one of the most difficult substrates to paint, therefore, correct surface preparation is paramount.

Galvanised surfaces will last for many years untreated and when exposed to the elements the bright finish will lose its brightness and tone down to a matt grey finish.

If weathering has taken place then the pre-treatment of the surface before painting may be different from that stated below.

Paint manufacturers offer different systems for painting galvanised steel and other non ferrous metals, therefore, they should be contacted and their recommendations strictly followed.

The following information is generic and for guidance only.

System and products,

Preparation.

Degrease with a suitable degreasing agent, methylated spirit or other cleaning solvents. For small areas hand etching with a suitable abrasive paper or cloth will improve the surface key. For large areas sweep blasting the surface to obtain a fine textured profile will provide a good surface for subsequent painting.

Mordant solution (T-Wash) should be applied to the prepared surface which on drying turns the bright metal surface black confirming the surface is clean and free from all contaminates.

Pre-treatment of galvanised surfaces

Priming

Products depending on manufacturer.

Priming coats can be either PVB Self etch primer, Zinc phosphate or general purpose primers. Undercoats and finishing materials can be oil or water based along with high performance epoxy and polyurethane protective coatings. Fire protection finishes are also specified.

Once the performance requirements have been decided, the manufacturers product data sheet should be obtained and instructions followed.

Note: PVB Self etch primers are susceptible to moisture and should be overcoated as soon as possible without exposure to high humidity or rain. Also the dry paint film is translucent so it is important to ensure the entire surface is coated.

In cases where painting of galvanised steelwork is required then steel fabricators often apply a holding primer before the steel is delivered to site. Under these circumstances it is important to establish what product had been used and consult the manufacturer for a recommended specification.

For further information on Zinc coated steel contact: British Galvanizers Association. 'What is Galvanizing-See:> https://www.galvanizing.org.uk/galvanizing-process/

Product illustrations provided by Bradite Limited. http://www.bradite.com

Dry Wood Rot

Wood Rot

Cause

Wood Rot: comes in two forms Dry and Wet. (see wet rot)

Dry Rot. The term implies that the timber is in a dry condition but it would normally have a moisture content reading of approximately 28%.

This along with a damp humid environment can lead to fungal growths forming on the timber.

Once the fungi spores /growths are established even though the moisture content of the wood has dropped and the cause remedied, the spores can still survive if the moisture content in the timber is still around 20%.

The fungi feeds on the wood and extracts the moisture/water which results in the wood structure becoming dry and brittle.

Remedy

The affected areas should be treated as soon as possible as the fungi spores can quickly spread. In domestic situations dry rot can often be found under floorboards at ground level where the air bricks are blocked. Other areas can be unvented cellars and roof spaces.

In these cases the assistance of a specialist wood preserving company should be sought.

For further information and specific advice contact:

https://www.rentokil.co.uk or search for local contractors

For wood repair systems: www.repair-care.co.uk windowcaresystemsang

Syneresis

Cause

Term applies when the oil and pigment content separates, the oil/volatile content is visible on the surface and soft settlement of the pigment takes place.

Solution

Thoroughly stir the separated contents with a palette knife (broad knife). If this is not done properly the paint coating may dry out with an uneven gloss or sheen finish.

Saponification

Saponification

Cause

A paint defect as a result of an oil based paint coming in contact with an alkali surface which had a high moisture content at the time of painting and not completely sealed with an alkali resistant primer.

Solution

Remove the soft/sticky film, wash down with white spirit, and allow to dry then apply an alkali resistant primer followed by overcoating with an oil based system.

Efflorescence

Cause

Efflorescence can originate from any cementitious building products such as brick, concrete blocks, sand: cement rendering and plaster. As moisture or moisture vapour passes through the materials to the surface it will bring any soluble salt deposits within the substrate to the surface. Initially the deposits appear fluffy and can be brushed off. If not removed this will crystalize, build up and damage the surface finish. The salts can remain dormant for many years and efflorescence can appear if the building substrate is affected by water ingress due to water leaks, flooding or a faulty damp proof lining.

Remedy

Decorating should be left until salts cease to appear by constant dry brushing. If painting is necessary then it is best to apply water based coatings of a high pigment content which allow moisture vapour to pass through the paint film more readily than others, allowing further salts to come to the surface without causing any major problems.

Some suppliers recommend treating the area with an alkali resisting primer sealer and while this will reduce any moisture vapour coming to the surface it is possible that any underlying salts could re-appear from the unsealed surrounding areas.

Yellowing

Yellowing

Cause

Yellowing and discolouration of an oil based paint excluded from normal sunlight.

White and pastel colours are mostly affected.

A newly applied coating to oak timber styles showing tannic acid bleed .

Bleeding from a wood knot which was not sealed with shellac knotting

Bleed from the underlying coating being bitumen based and activated by the solvents in the finishing material.

Remedy

No solution for the those areas excluded from daylight other than using waterbased paints.

Where hardwood requires painting a leafing/flake base aluminium primer should be used.

Also see: Discolouration

Frost Damage

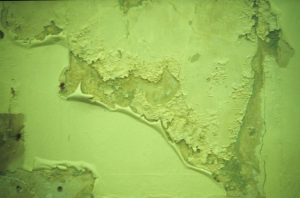

Frost damaged paint

Although water based paints will withstand low temperatures they should always be stored above 5 degrees centigrade.

The illustration shows the result of paint being subjected to extreme low temperatures and has frozen, rendering the product unusable.

Crows footing

Crows footing

Cause

Problems of this type occur when coatings, particularly water based paints are applied onto a surface which has a higher sheen level resulting in the adhesion quality of the newly applied paint being low, for example a matt emulsion being applied over a vinyl silk or an oil based coating.

It can also occur when water based paints are applied to new plaster without being thinned as a sealer coat. This can result in the VOC's (Volatile Organic Compound) being quickly absorbed into the surface resulting in poor adhesion of the coating. Consequently, as the newly applied paint hardens the tensile strength of the newly applied paint film begins to shrink and cracks in the paint film appear.

Solution

After rubbing down and face filling with a fine plaster filler, applying a paint coating of a higher sheen level will in most cases overcome the problem.

Crinkling

Crinkling

Cause

Softening of a previously applied coating caused by applying a subsequent coat before the underlying paint film is totally dry. Problems of this nature can also be as a result of applying paints such as chlorinated rubber which contain strong solvents over alkyd based paint finishes.

This type of problem can also occur when water based coatings are applied over an oil based sealer such as Alkali Resisting Primer or Stabilising Solutions for use onto a powdery substrate. And where the sealer coat has remained glossy and not flatted down before applying the top water based coats..

Solution

Occasionally it may be possible to remove the ridges. In severe cases complete removal may be necessary before re – painting can take place.

See Rivelling

Ropiness

Ropiness

Cause

Ropiness of a paint coating caused by the material being high in viscosity (thick), with very little flow. This also occurs when paints of normal viscosity are applied without care.

Solution

The ‘ropy’ finish must be thoroughly dry and flatted down with carborundum paper (wet or dry) used wet, with water as a lubricant. If repainting with the same product adjust with appropriate thinning agent to the correct viscosity before re–painting.