Settlement

Settlement

Cause

This can occur not only in paint which has been stored for a long time but also in relatively new material, i.e. hard or soft settlement.

Remedy

Thoroughly stir the product and ensure the settled pigment/solids are fully dispersed into the material. Although stirring with a palette knife (broad knife) will generally suffice, mechanical mixing or high speed paint shakers. may be preferred.

Cissing

Cissing

Cissing

Cause

This defect is caused by a paint coating being applied to a surface which has been contaminated with oil, grease, or polish causing the wet film to creep back exposing the underlying surface. This type of problem can also occur when coatings are applied to surfaces which have previously been treated with a silicone based product, contaminated with body fats including hair sprays etc. In extreme cases where the coating flows back from a large area of the surface, the term crawling is sometime used.

Solution

Once the coating has completely dried and the general adhesion is satisfactory, thoroughly flat down to a smooth surface

using wet or dry carborundum paper wet. After rinsing and ensuring the surface is free from all contaminates re-paint as required.

Mould

Mould

Cause

Organic mould on an interior wall surface which has penetrated into the plaster caused by damp, humid conditions.

This is generally caused by the lack of airflow within the area by keeping windows and doors closed. Allowing air to circulate freely from humid areas, such as bathrooms and kitchens should be standard practice. It should also be recognised that by turning the heating up, increasing the air temperature, a higher moisture content is held in the atmosphere and when in contact with colder surface condensation can rapidly occur.

The restricted airflow from humid conditions can result in mould forming in corners of rooms and behind household furniture.

Remedy

Allowing air to move freely to escape from humid areas such as bathrooms and kitchens should be standard practice.

It should also be recognised that by turning the heating up, more moisture can be held in the atmosphere and if allowed to settle onto a cooler surface condensation can rapidly occur onto wall surfaces.

Washing down with a solution of bleach and water can help to remove the mould, although proprietary fungicidal solutions may prove to be more effective.

Washing down should not be confined to the affected area but should include all adjacent walls and ceiling areas.

If the organic matter cannot be removed then it may be necessary to “hack off” and re-plaster.

Water Based Paint Flaking

Water based Paint Flaking

Cause

A breakdown as a result of an emulsion paint being applied over an under-bound material such as distemper.

Solution

Remove completely back to bare plaster by scraping and washing. In some cases the application of a hot glue size over the emulsion can result in blistering occurring and making this coating more easy to remove.

Resin Bleed

Resin Exudation

Cause

Resin and sap residue is not unusual where knots are present in wood.

A change in temperature can cause the natural resin to be activated and bleed to the surface. The practice years ago was to extract the resin by heat, burning out resinous knots before painting, but today this practice rarely happens.

The hard wood knots can also contain tannic acid which if not sealed will lead to yellowing of light coloured oil based paints.

Remedy

Remove excessive resin with solvent such as white spirit.

For wood translucent finishes sand down and seal all knots with clear shellac (knotting) followed by a conventional alkyd system of primer, undercoat and gloss.

In some cases if the resin in the hard wood veins is excessive, a leafing aluminium based primer should be considered.

Note: While the shellac knotting will reduce the possibility of yellowing it will not stop the resin coming to the surface.

Where the presence of resin is extreme then the only action is to have the timber replaced.

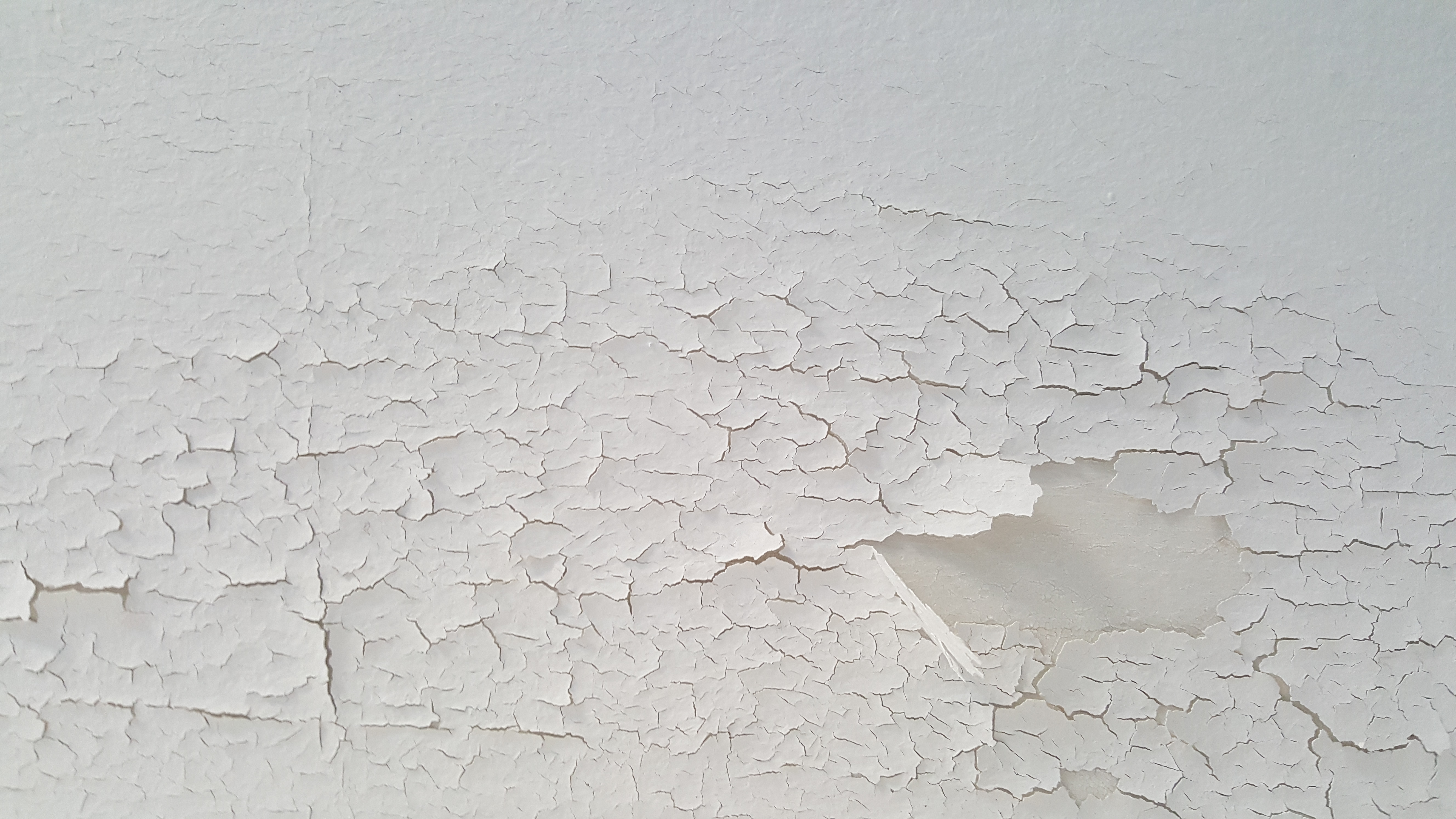

Mud Cracking

Cause

Caused by the application of a pigmented matt emulsion over a surface previously finished with a vinyl silk emulsion. This is where the adhesion of the most recently applied coating is poor and the underlying material offers no keying properties for when the last coat of paint is applied.

Remedy

Rub down with a “Scotch Brite” pad and apply a thinned-down coat of good quality vinyl matt emulsion. If this fails to cure the problem then an acrylic primer should be tried. It may be necessary to reinstate with a vinyl silk or satin emulsion.

Mud Cracking

Cause

Caused by the application of a matt emulsion over a surface previously finished with a vinyl silk emulsion. This is where the adhesion of the most recently applied coating is poor with the underlying silk finished material offering no keying properties for the newly applied matt finish.

Remedy

Rub down with suitable abrasive paper and to a trial area apply a coat of good quality vinyl matt emulsion, thinned a necessary. If this fails to cure the problem, then an acrylic primer should be tried. It may be necessary to reinstate with an emulsion or acrylic with a higher sheen finish.

Copper corrosion

Cause

Copper corrosion is caused when oxygen and water come in contact with untreated copper that is exposed to air and moisture in the atmosphere. This is also referred to as copper carbonate and copper hydroxide.

Solution

Remove the contamination with a solution of acetic acid (vinegar); salt can also help to clean a copper surface. There are also many household products available which will be successful.

If untreated copper is required to be painted then primers for non ferrous metals are available. For domestic heating and plumbing systems clean and abrade the copper surface followed by priming and finishing with suitable oil based paint systems.

If the bare copper appearance is preferred then treating with a clear shellac or clear lacquer can be considered.

Note: Black spots can appear when oil based coatings are applied to an unclean surface.

Rivelling

Rivelling

Cause

Two problems in one. General poor application causing the material to sag and shrivel. Rivelling is caused by the film of a thick coating drying too quickly and skinning before the underlying material is dry.

Remedy

Once the entire coating is dry and hard, flat down using wet or dry carborundum paper, wet, with warm water and add soap. Thoroughly rinse with clean water and allow to dry before re-painting with additional coats.

Moisture ingress

Moisture ingress

Cause

Old defective putties allowing moisture ingress into the timber resulting in the wood splitting and corrosion of the glazing pins.

Remedy

Hack out the old putties and replace after priming the rebates. Burn off remaining paint coatings followed by thoroughly sanding down, clean nail heads or replace.

Treat knots, etc. if present and prime overall. A general purpose primer suitable for wood and metal is usually recommended as this will contain rust inhibitive pigments.

This should be followed by an undercoat and finishing system oil or water based.

Chalking Oil Paints

Chalking of resin based paints.

Cause

Overall or partial chalking and loss of gloss is due to the erosion of the paint film being exposed to UV light.

Certain colours contain pigments that are not light fast, therefore are more inclined than others to fade and chalk with age when exposed to ultra violet rays.

Solution.

Wash down with sugar soap and water, rinse, allow to dry, sand down and paint with the required system.