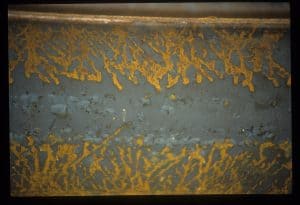

Corrosion of Steel

Corrosion of steel from new to painting. When steelwork is produced from molten iron and passes through the mill to form shape when cooled it is light blue in colour and known as Mill Scale.

This finish is where the layer of of molten steel is deposited back onto the fabricated body of produced steel items such as stanchions and girders. This layer of the molten steel needs to be removed before painting. This can be done byway of natural weathering, grit/sand blasting, flame cleaning or acid cleaning.

|

|

|

|

| Mill Scale | Weathering commenced | Flaking of the mill scale | Rust removed by any of the above methods including wire brushing |

During natural weathering the layer of mill scale becomes detached and once removed the surface will be left with very fine particles of steel referred to as Rust.

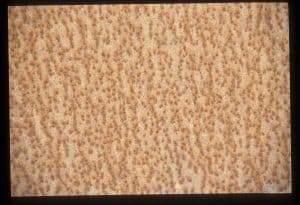

Crackle finish

Special finishing paint formulated to shrink and form cracks in the dry film exposing the underneath colour.

Usually applied to furniture to leaving a distressed finish.

Results similar appearance to mud cracking.

Cratering

Caused by rain falling onto a semi dry paint film or aeration of a paint coating during application.

Cross Hatch Adhesion Testing

Cross Hatch Adhesion Testing

A cross hatch adhesion test is used to check the adhesion of a coating over the applied substrate.

This is by drawing over the surface the cutting blades and then firmly applying clear adhesive tape applied over the hatch markings

and on removal the adhesion result is based on the amount of paint product is removed .

For further information see: https://www.elcometer.com/en/coatings-inspection/all-coatings-inspection.html

Cross Lining

Hanging lining paper horizontally to cover surface imperfections before hanging standard wallpaper in a vertical direction.

Cup Gun

A conventional air assisted spray gun with the paint supplied from a reservoir fitted either on top or underneath the gun.

A decorative moulding used between a wall and ceiling line.

A decorative moulding used between a wall and ceiling line. The formation of ridges and hollows in a paint or varnish coating.

The formation of ridges and hollows in a paint or varnish coating. Wrinkling of the paint film which forms a pattern similar to a crow's foot.

Wrinkling of the paint film which forms a pattern similar to a crow's foot.