Masking and Protection of surfaces 2

Protection of Surfaces

Different types of covering sheeting/foils are available to suit all eventualities where care is required to protect clients furnishings and fittings when interior/exterior projects are carried out.

|

Absorbent Fleece

Re-usable and absorbing covering fleece for all kinds of surfaces absorbing fleece on the upper side waterproof PE coating with non-skid bottom. |

|

|

Plasterers Covering

High quality covering foil for most applications. |

|

|

Self Adhesive Floor Coverings

Self adhesive protection foil for surfaces like wood, laminate flooring, tiles and stones the adhesive layer is on the outside of the roll, therefore easy to roll out high protection against damage or pollution clean removable up to two months. |

|

|

COVERING FLEECE AIR

self-adhesive breathable protection fleece - lightweight and very strong breathable and liquid proof - clean removable up to two months after instalment |

|

|

WILTEC CARPET COVER

Transparent protective film for soft surfaces such as carpet and flooring with an adhesive layer on the outside, so easy roll out - can be left for up to two before removal after providing high protection against damage or contamination. |

|

|

AUTOWRAP FOIL

White protection foil with adhesive layer - designed to protect painted surfaces from weather and minor mechanical damage - resistant to chemicals and easy to remove |

Masking and Protection of Surfaces 1

MASKING AND PROTECTION OF SURFACES

The final results of any project is reflected on the standard of decorative finish with the paintwork along with the protections of surfaces.. Masking tape plays an important part and the correct usage of tape will help to provide the final finish..

MASKING TAPE EXTREME MASKING TAPE EXTREME

Special reinforced rice paper (washi) masking tape -for slightly wet and rough surfaces - no paint bleed (sharp paint lines) - indoor and outdoor use - 4 months UV-resistant - resistant to temperatures up to 100 °C - never any glue residue. |

MASKING TAPE 60 MASKING TAPE 60

Paper masking tape resistant to temperatures up to 60°C - used by professional painters - and industrial use, does not leave any glue residue - masking paper with standard crepe tape - ideal for effortless and fast masking small surfaces like window- sills and skirting boards - leaves no adhesive residue up to 24 hours |

MASKING TAPE PURPLE

Special rice paper (washi) masking tape - low tack tape for sensitive surfaces like wallpaper, fresh paint etc. no paint bleed (sharp paint lines) - resistant to temperatures up to 50°C - never any glue residue up to 4 months |

MASKING TAPE GOLD

Special rice paper (washi) masking tape - no paint bleed (sharp paint lines) - indoor and outdoor use - 6 months UV-resistant to temperatures up to 100 °C - never any glue residue |

QUICK MASK GOLD QUICK MASK GOLD

Static masking foil with original Masking Tape Gold - ideal for effortless and fast masking - suitable for indoor and outdoor use - ideal for creating sharp paint lines - leaves no adhesive residue up to 6 months |

Product illustrations courtesy of Deltechtape NL. https://www.deltectape.com https://youtu.be/4OdBOlWo4ws

Other masking tape and protection companies include:

https://www.tesa.com/en-gb/craftsmen/tesa-and-the-pda

file:///C:/Users/User/Downloads/tesa-professional-product-catalogue-2016%20(2).pdf

Tesa: https://www.tesa.com/en-gb/consumer/renovation

Q1 Tapes: https://www.q1tapes.com/en/painting

Waste Disposal (Paint and Hazardous Liquids)

Waste Disposal.

|

|

On construction site the disposal of building waste including paint and hazardous materials and liquids should be cover at your site induction toolbox talk.

At this time information advising the location areas of the disposal facilities should be included.

Checks should be made with the local authorities regarding the local facilities and regulations for commercial and domestic wastage.

Under no circumstances should paint products be disposed of into the nation water drainage system.

Part used paint containers should be filled with either sand or sawdust to consolidate the liquid and allow to dry be for disposal.

Dirty solvent (white spirit etc.) is classified as hazardous and should labelled according as this type of product can be reclaimed.

Tips

Part tins of water based paints are available they could be offered to a local community organisation. https://communityrepaint.org.uk/

Dirty solvents. After washing out brushes/rollers sleeves the solvent can be reclaimed for future use by transferring into a larger container. Once the solids have settled to the bottom the solvent can be syphoned off and reused.

A number of decorators merchants such as Johnstone Paints, Dulux and Crown Decorating Centre offer facilities where they will

take back used paint containers. Check local branch for terms and conditions.

Site Signage

Site Signage

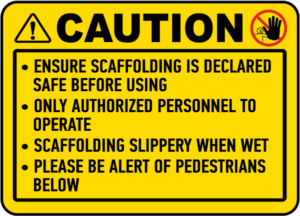

Warning Signs. Yellow triangle with a Black border to alert of all possible dangers on site.

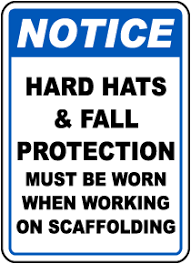

Mandatory Signs. Blue and White and must be obeyed i.e. Hard hats and footwear must be worn.

Prohibition Signs. Red circle with a Red line with Black images with White text on a Red background.

Safe Working Conditions Signs. Rectangular Green signs with White writing giving general information relating to First aid - Assembly points and First aid stations

Fire Equipment Signs. Red rectangular with White wording.

Note: Safety is the responsibility of all site personnel and if any unsafe observations are noted then immediate action in notifying line managers or resident H&S Officer should be made.

Site Testing Equipment

Site Testing Equipment. Under Construction.

Site Testing Equipment. Under Construction.

Site testing equipment should be appropriate for the work in hand and can vary from a standard moisture meter to those require to check the paint system used, film thickness and adhesion.

Pinhole detector see: Glossary of Terms Decorators. https://www.elcometer.com/coatings-inspection/all-coatings-inspection/pinhole-porosity-detection.html

Dry Film Thickness Gauge see:: Glossary of Terms Decorators. https://www.elcometer.com/en/coatings-inspection/all-coatings-inspection/dry-film-thickness/digital/elcometer-456-separate-coating-thickness-gauge.html

MDF Adhesion of applied Coatings

MDF Adhesion Problems

Cause

Paraffin wax is often used in the manufacture of MDF to improve the water resistant properties.

Some of the wax treatment can remain on the surface and can affect the adhesion of primer coating when applied without any form of preparation.

Lightly sand down and wipe over with Methylated Sprit and allow to dry.

Check that the selected paint manufactures priming coat is suitable and if necessary apply to a prepared to check the adhesion.

Site Induction

Site Induction, is carried out to ensure all personnel working on the the site is familiar with the Health and Safety requirements.

Health and Safety Induction Checklist

Induction & Method signing register SITE example