Corrosion of Steel

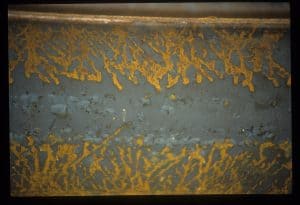

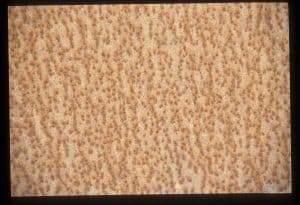

Corrosion of steel from new to painting. When steelwork is produced from molten iron and passes through the mill to form shape when cooled it is light blue in colour and known as Mill Scale.

This finish is where the layer of of molten steel is deposited back onto the fabricated body of produced steel items such as stanchions and girders. This layer of the molten steel needs to be removed before painting. This can be done byway of natural weathering, grit/sand blasting, flame cleaning or acid cleaning.

|

|

|

|

| Mill Scale | Weathering commenced | Flaking of the mill scale | Rust removed by any of the above methods including wire brushing |

During natural weathering the layer of mill scale becomes detached and once removed the surface will be left with very fine particles of steel referred to as Rust.

Covering Power:

Referred to by many when expressing their views relating perhaps to the hiding power, (see Opacity), coverage, (see spreading rate).

Cracking

The splitting of a paint or varnish coating due to ageing, (see Hairline cracking, Checking, Crazing).

Crackle finish

Special finishing paint formulated to shrink and form cracks in the dry film exposing the underneath colour.

Usually applied to furniture to leaving a distressed finish.

Results similar appearance to mud cracking.

Cratering

Caused by rain falling onto a semi dry paint film or aeration of a paint coating during application.

Crawling

Paint shrinking during drying forming an uneven film mainly due to surface contamination Creepage

High surface tension paints applied to a substrate with lower surface tension. For example, paint on steel with oil on the surface